V-PROJECT.X4

寿命と耐環境性を検証中!

Testing for lifespan and environmental resistance!

PROJECT

寿命と耐環境性を検証中!

Testing for lifespan and

environmental resistance!

V-Generatorは半永久に使え、温度やその変化に対しても強いと思います。振動発電研究室では、これらを実証する試験を実施中です。その途中結果を報告します。上の写真(左)は寿命を検証する疲労試験の様子です。デバイス(Type S)を加振機にボルトで締結し、適当な錘を取り付け、共振で振らせます。この時、デバイスの振幅をパラメータとし、何回の振動で壊れたかを記録します。デバイスは常に共振になるよう周波数を制御しています。概して、大きな振幅で振らせれば直ぐに壊れます。逆に小さな振幅で振らせれば壊れるまでの回数は大きくなっていきます。そして振幅がある値以下なら壊れなくなります。これは一般的な機械部品のS-N曲線から推測されます。なおこの試験はデバイスを振動させた試験で、個々の構成部品ではなく、実動作で不良を引き起こす全ての要素を含んだ試験になっています。例えていえば機械の寿命を測定するような試験になります。

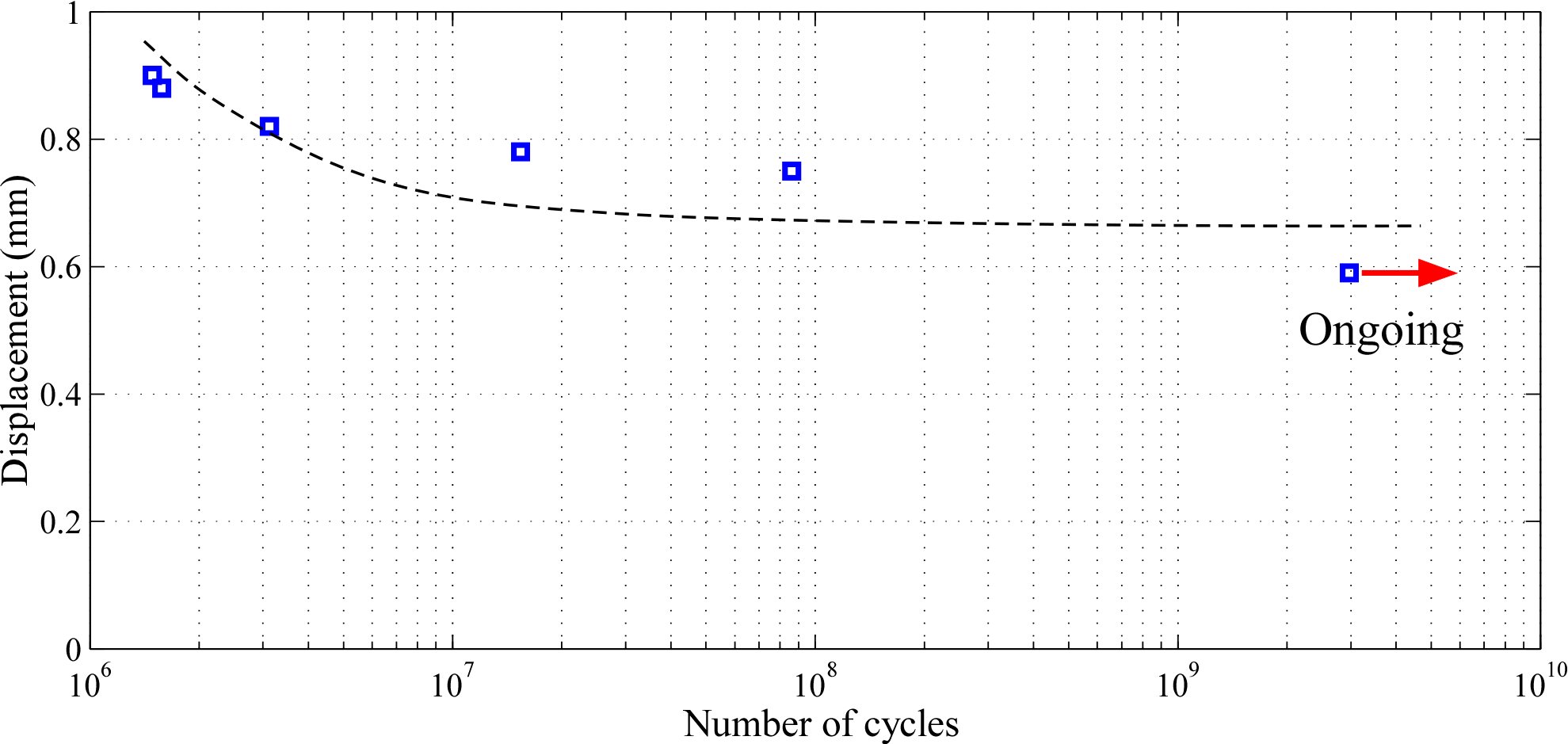

その結果が図1です。一般的なS-N曲線に近いかたちになっています。2022年11月現在、変位が0.6 mmの試験を継続中で、30億回の振動でも壊れずに動作しています。10年、20年と測定したわけではありませんが、S-N曲線から予想されるに、この変位において、ほぼ半永久の寿命を持つと推測されます。

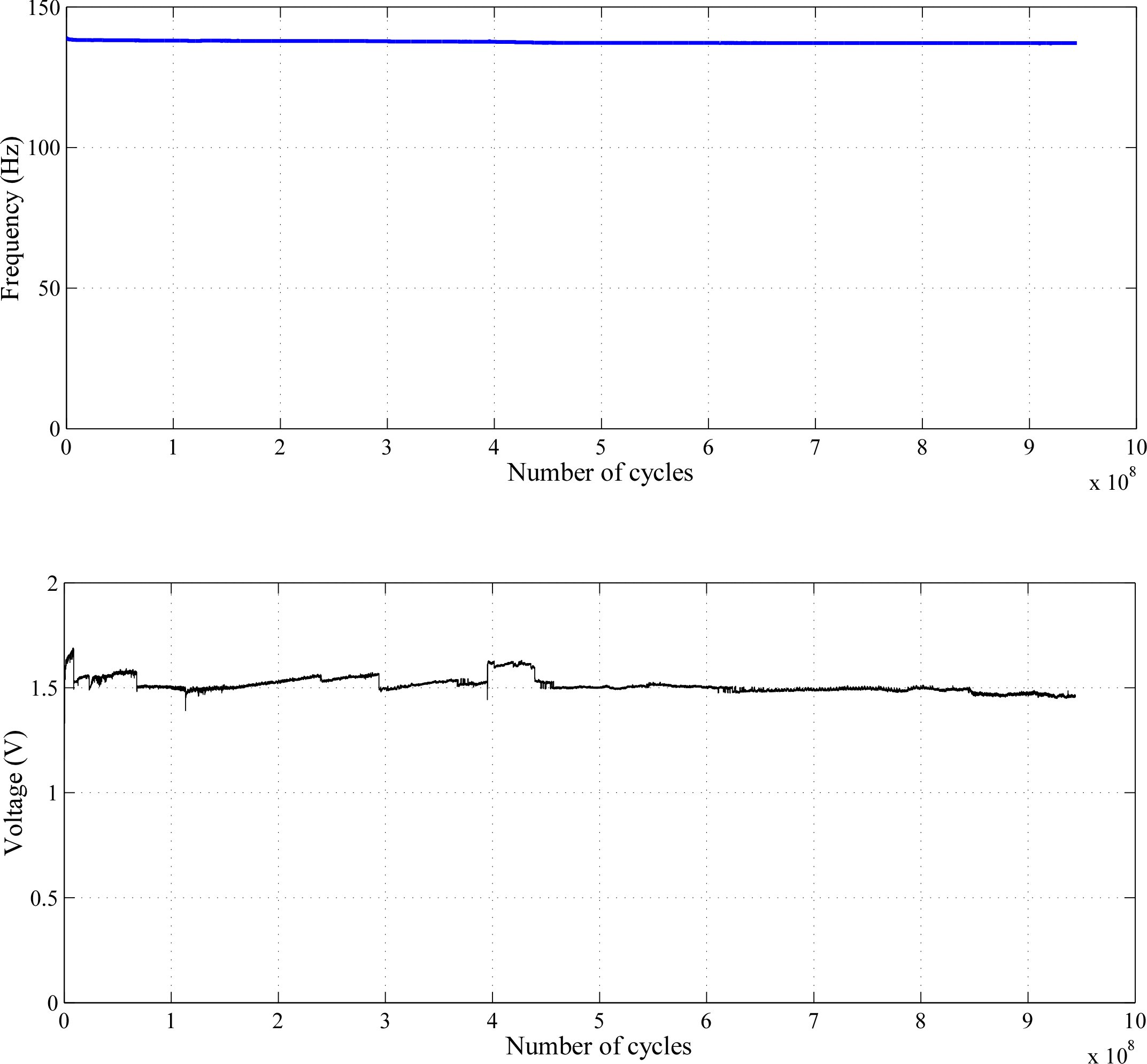

なお、この変位が0.6 mmの場合の共振周波数、電圧、磁束密度の変化の回数履歴を図2に示します。共振周波数は変化せず、また電圧も初期の状態を維持しています。またこれが磁歪素子の磁束密度の変化(逆磁歪効果)に起因していることもわかります。磁束密度の変化は1Tで、素子をフル活用している状態です。つまり図1で素子変位が0.75mm以上の場合に壊れましたが、実際、0.6 mm以上の変位で振動させる必要はありません。

The V-Generator is designed to be used semi-permanently and is resilient to temperature and its variations. In our Vibration Power Generation Laboratory, we are conducting tests to demonstrate these characteristics. We would like to report some interim results. The photo above (left) shows the fatigue testing conducted to verify its lifespan. The device (Type S) is bolted to a vibration exciter, and an appropriate weight is attached to induce resonance. During the test, we record the number of vibrations required for the device to break, with the device always controlled to resonate. Generally, if the device is subjected to large amplitudes of vibration, it breaks quickly. Conversely, if it is subjected to small amplitudes, the number of vibrations until failure increases. Once the amplitude is below a certain threshold, the device no longer breaks. This can be inferred from the S-N curve commonly observed in mechanical components. It is important to note that this test involves subjecting the device to vibrations, taking into account all elements that can cause malfunctions in actual operation, rather than testing individual components. It can be likened to measuring the lifespan of a machine.

The result is shown in Figure 1, which closely resembles a typical S-N curve. As of November 2022, the test with a displacement of 0.6 mm is still ongoing, and the device has been operating without failure even after 3 billion vibrations. Although we have not measured its lifespan for 10 or 20 years, based on the S-N curve, it is estimated to have a nearly semi-permanent lifespan at this displacement.

In addition, Figure 2 shows the number of variations in resonance frequency, voltage, and magnetic flux density for the case of a displacement of 0.6 mm. The resonance frequency remains unchanged, and the voltage maintains its initial state. It is also evident that these variations are caused by the change in magnetic flux density (magnetostrictive effect) of the magnetostrictive element. The change in magnetic flux density is at 1 Tesla, which represents the full utilization of the element. This means that the device broke when the displacement exceeded 0.75 mm, but in practice, there is no need to subject it to displacements greater than 0.6 mm.

図1 素子変位と壊れるまでの回数

2022年11月現在、試験を継続中。一般的な繰り返し疲労強度のS-N曲線に乗った特性を示すことがわかる。つまり上限の振幅を設定すれば永続的に使えると予測される。

Figure 1: Device Displacement and Number of Vibrations until Failure

As of November 2022, the test is still ongoing. It can be observed that the device exhibits characteristics that align with the typical S-N curve for fatigue strength. This implies that by setting an upper limit for the amplitude, it is predicted to have a long-lasting usability.

図2 素子変位が0.6mmの場合の共振周波数(上)、発生電圧(中)、磁束密度変化(下)の振動回数による履歴

7.5億回付近の不連続点は、一度、試験装置を止め暫くの間を空けて再度、試験を開始したためである。共振周波数は137Hzでほとんど変化しない。実際は、試験開始直後に1Hzほど低下している。これはボルトによる錘や固定の締結が振動で馴染む過程によると推測される。

Figure 2: History of Vibration Cycles for Resonant Frequency (top), Generated Voltage (middle), and Magnetic Flux Density Variation (bottom) at Device Displacement of 0.6mm

The discontinuous points around 750 million cycles occurred when the test apparatus was stopped for a while and then restarted. The resonant frequency remains nearly constant at 137Hz, with a slight decrease of approximately 1Hz observed immediately after the test started. This decrease is likely attributed to the process of the weights and fixtures attached by bolts settling into the vibrations.

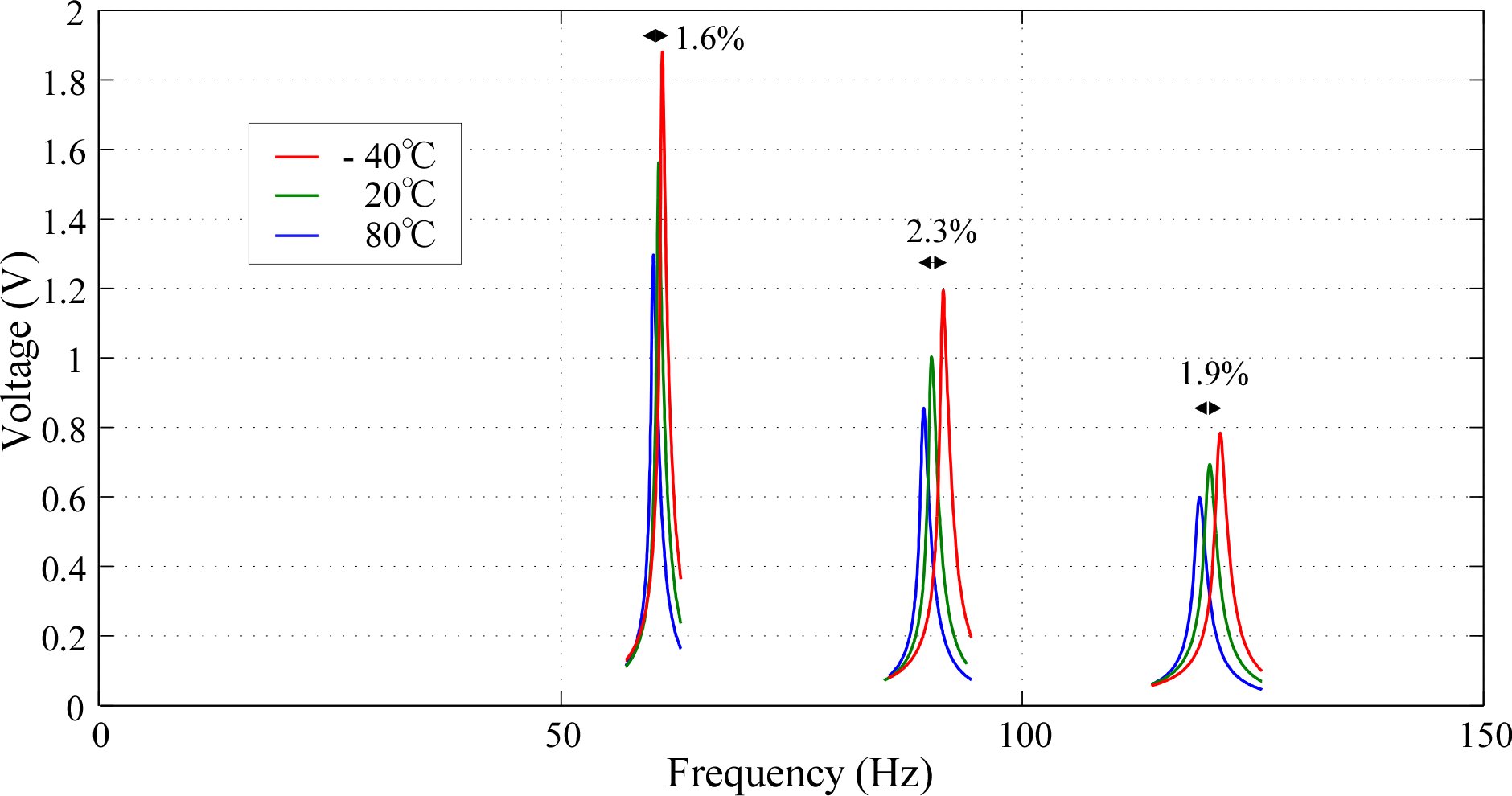

温度に対する共振周波数の変化も検証しています。その結果が図3です。恒温槽の中でデバイスを振らせ(錘は3パターン)、雰囲気温度が20℃、-40℃、80℃の場合の周波数特性を比較しています。結果、温度が変化しても共振周波数はそれほど変化しないことがわかります。実際には1.6~2.3% (-40℃~80℃の共振周波数の変化幅/20℃の共振周波数) 変化しています。ただ、この変化は構造的な工夫や電力変換回路などで対応できる範囲です。また実際の用途で、雰囲気温度が-40℃から80℃まで変化する環境はよほど特殊な場合を除きほとんどありません。

We have also conducted verification of the resonant frequency variation with temperature. The results are shown in Figure 3. The device was vibrated with weights in a constant temperature chamber, and the frequency characteristics were compared at ambient temperatures of 20°C, -40°C, and 80°C. The results indicate that the resonant frequency does not change significantly with temperature. In actuality, there is a variation of approximately 1.6-2.3% (change range of resonant frequency from -40°C to 80°C divided by resonant frequency at 20°C). However, this variation can be accommodated within the range of structural design considerations and power conversion circuits. Furthermore, in practical applications, environments where the ambient temperature varies from -40°C to 80°C are rarely encountered unless under highly specific circumstances.

図3 共振周波数の温度依存性のグラフ

20℃、-40℃、80℃、の各々の場合を計測。温度変化120℃で共振周波数の変化は2.3%程度。概して温度が高くなるにつれ電圧が下がるが、これは低温でよくなるFe-Ga合金の特性と素子のバイアス状態のずれなどが原因と推測される。なお温度サイクルを加えても特性は劣化しない。

Figure 3 depicts the temperature dependency of the resonant frequency. Measurements were taken at 20°C, -40°C, and 80°C. The resonant frequency exhibited a change of approximately 2.3% over a temperature variation of 120°C. Generally, as the temperature increases, the voltage decreases, which is attributed to the characteristics of the Fe-Ga alloy improving at lower temperatures and potential shifts in the bias state of the device. It is worth noting that the characteristics remain unaffected even when subjected to temperature cycling.

再度、雰囲気温度が60℃で連続的に動作させた場合の共振周波数と電圧の履歴を図4に示します。これは図2と同様なグラフで、60℃の場合でも共振周波数は変わらず、また電圧も維持されることがわかります。温度が室温より高い雰囲気下においても特性の劣化がなければ、共振周波数は変化せず、また半永久の寿命を持つと推測されます。

Figure 4 represents the history of resonant frequency and voltage when the device is continuously operated at an ambient temperature of 60°C. Similar to Figure 2, it can be observed that the resonant frequency remains unchanged at 60°C, and the voltage is also maintained. This indicates that even in an atmosphere with a temperature higher than room temperature, there is no degradation in the device’s characteristics. Therefore, it can be inferred that the resonant frequency remains constant and the device exhibits a nearly perpetual lifespan.

図4 雰囲気温度が60℃の場合の共振周波数(上)と発生電圧(下)の振動回数による履歴

室温と同様に共振周波数と電圧は回数を経ても変化しない。途中の不連続点は、試験装置を止めて再度、開始したためである。実際は、試験開始直後に1.5 Hzほど低下しているが、これはボルトによる錘や固定の締結が振動で馴染む過程によるものと推測される。

Figure 4 shows the history of resonant frequency (top) and generated voltage (bottom) in relation to the number of vibrations when the ambient temperature is set at 60°C. Similar to room temperature, both the resonant frequency and voltage remain unchanged over the course of the vibrations. The discontinuities in the graph are due to the interruption and subsequent resumption of the test apparatus. In actuality, there is a slight decrease of approximately 1.5 Hz immediately after the test resumes, which is likely attributed to the bedding-in process of the bolted weight and fixture due to vibrations.

V-Generatorの寿命が長く、耐環境性が高い理由について、V-Generatorは鉄の構造体で、原理上、摩耗する部分はありません。「錆びて劣化しませんか?」と聞かれますが、まずメッキやコーティングなど錆対策は様々にあります。仮に表面が錆びたからといって使えなくなることはありません。温度に対しても、よほどの高温でない限り、磁性がなくなることはありません。磁性があれば逆磁歪効果が発生します。温度やその変化について、これが影響するのはバネ性と熱膨張、接着剤の強度、永久磁石の磁力とコイルの電気抵抗です。バネ性は温度に依存しますがそれほど変化しません。更にV-GeneratorのフレームとFe-Ga合金の熱膨張係数は同程度です。結果、熱膨張の影響を受けにくくなっています。永久磁石とコイルの耐熱性について、これらはモータの主要部品で、高温や低温でも使われています。

動作時の疲労強度について、図1のグラフの左のように相当な振動を加えれば壊れます。それはどのような機械でも同じです。壊れる要素は(1)フレームの破断、(2)Fe-Ga合金の剥離、(3)コイルの断線、(4)錘や固定部のネジ締結の緩みです。(1)については、振幅を制限すれば発生しません。発生するのは相当な振動の場合です。(2)は生じますが、これも相当な振動の場合で、振幅を制限すれば生じません。(3)は振動することによる疲労で、この対策も必要ですが、相当な振動の場合です。(4)の緩みについては、図2と図4の結果で示すよう締結を十分にすれば大丈夫と考えられます。

V-Generatorの寿命や耐環境性を検証する試験は様々な現場でも進行中です。工場の非常に強度な振動や屋外でも長期間に亘り動作しています。

The longevity and environmental durability of the V-Generator can be attributed to its construction using iron, which inherently lacks wearing components. We often receive inquiries about rust and degradation, but various anti-rust measures such as plating and coating can be applied. Even if the surface rusts, it does not render the device unusable. In terms of temperature, unless exposed to extremely high temperatures, the magnetic properties of the V-Generator do not diminish. If the device retains its magnetism, the inverse magnetostrictive effect occurs. Temperature and its fluctuations primarily affect the spring properties, thermal expansion of the frame, adhesive strength, magnetic force of permanent magnets, and electrical resistance of the coil. The spring properties have some temperature dependence but generally exhibit minimal changes. Additionally, the thermal expansion coefficient of the V-Generator’s frame is comparable to that of the Fe-Ga alloy, resulting in reduced susceptibility to thermal expansion effects. As for the heat resistance of the permanent magnets and coils, they are commonly used in motors and can withstand high and low temperatures.

Regarding the fatigue strength during operation, as shown on the left side of the graph in Figure 1, the V-Generator can break if subjected to significant vibrations. This holds true for any machinery. The elements that can lead to failure are (1) frame fracture, (2) delamination of the Fe-Ga alloy, (3) coil breakage, and (4) loosening of weights and fasteners. (1) can be prevented by limiting the amplitude of vibrations. Fracture occurs only under significant vibration conditions. (2) may occur under severe vibrations, but it can be prevented by limiting the amplitude. (3) is fatigue-related due to vibrations, and countermeasures are necessary, but it also requires significant vibration conditions. Regarding (4), the results in Figures 2 and 4 indicate that sufficient fastening can prevent loosening.

Verification tests for the lifespan and environmental durability of the V-Generator are currently being conducted in various fields. It has undergone operation under intense vibrations in factories and long-term outdoor settings.